Summer-Sale bis 31.08.2024

5 Wochen am Stück Mega-Preise für alle die bisher gezögert haben

Mein Ziel ist es hier eine Basis für „Schleifverrückte“ zu schaffen.

Ich besitze und bespreche hier folgende Geräte:

Alle von mir im Shop angebotenen Dinge verwende ich auch selbst.

Nachdem es sehr umständlich war in Deutschland an CBN-Wheels zu kommen mit denen man auch

mit klarem Wasser schleifen kann, habe ich mich entschlossen etwas dagegen zu tun..

Auch wurde ich immer wieder nach Bezugsquellen gefragt für meine Tools.

Also habe ich beschlossen diese in begrenzter Stückzahl herstellen zu lassen, um diese der

Community zugänglich zu machen.

Kundenbewertungen

Ich schleife und Berichte darüber, auf folgenden Maschinen:

Tormek T8 (mit verschiedenen Modifikationen)

Hier verwende ich selbstgebaute Toolbars, Pin Pivot Collars und einen Adapter, den ich montiere,

wenn ich mehrere Messer hintereinander schleife. Hierbei montiere ich mittels des Adapters 2

Schleifscheiben an der Tormek so kann ich den 400er und danach gleich den 1000er Stein

nacheinander schleifen, ohne umzurüsten. Dies ist besonders dann sinnvoll, wenn ich mehrere

ähnliche Messer am Stück schleifen will.

Bei den Schleifsteinen bin ich seit 6 Monaten auf CBN-Rädern unterwegs. Diese haben 160, 400 und

1000 Grit FEPA. Diese können in klarem Wasser laufen ohne das teure Fluid. Wenn man die Haltbarkeit der

Wheels aufrechnet wie viel Fluid man dafür verbraucht könnte man meiner Rechnung nach 2 Wheels

kaufen. Die ersten Kundenmeinungen könnt ihr gerne im Shop nachlesen. Die Qualität der Wheels ist absolut überzeugend und hebt das schleifen auf ein anderes Level.

Zum exakten einstellen des Schneidwinkels habe ich eine eigene Software entwickelt. Diese ist in meinem Shop für Windows zu haben. Es gibt 2 Ausführungen. Einmal speziell für die Tormek T8 mit fest eingestellten Werten und zum anderen eine „Universal“ Version für viele Maschinen verwendbar nach eintragen zweier Maße. Eine Version für Android ist im Playstore verfügbar. Die IOS Version ist in Arbeit und wird in den nächsten Wochen verfügbar sein.

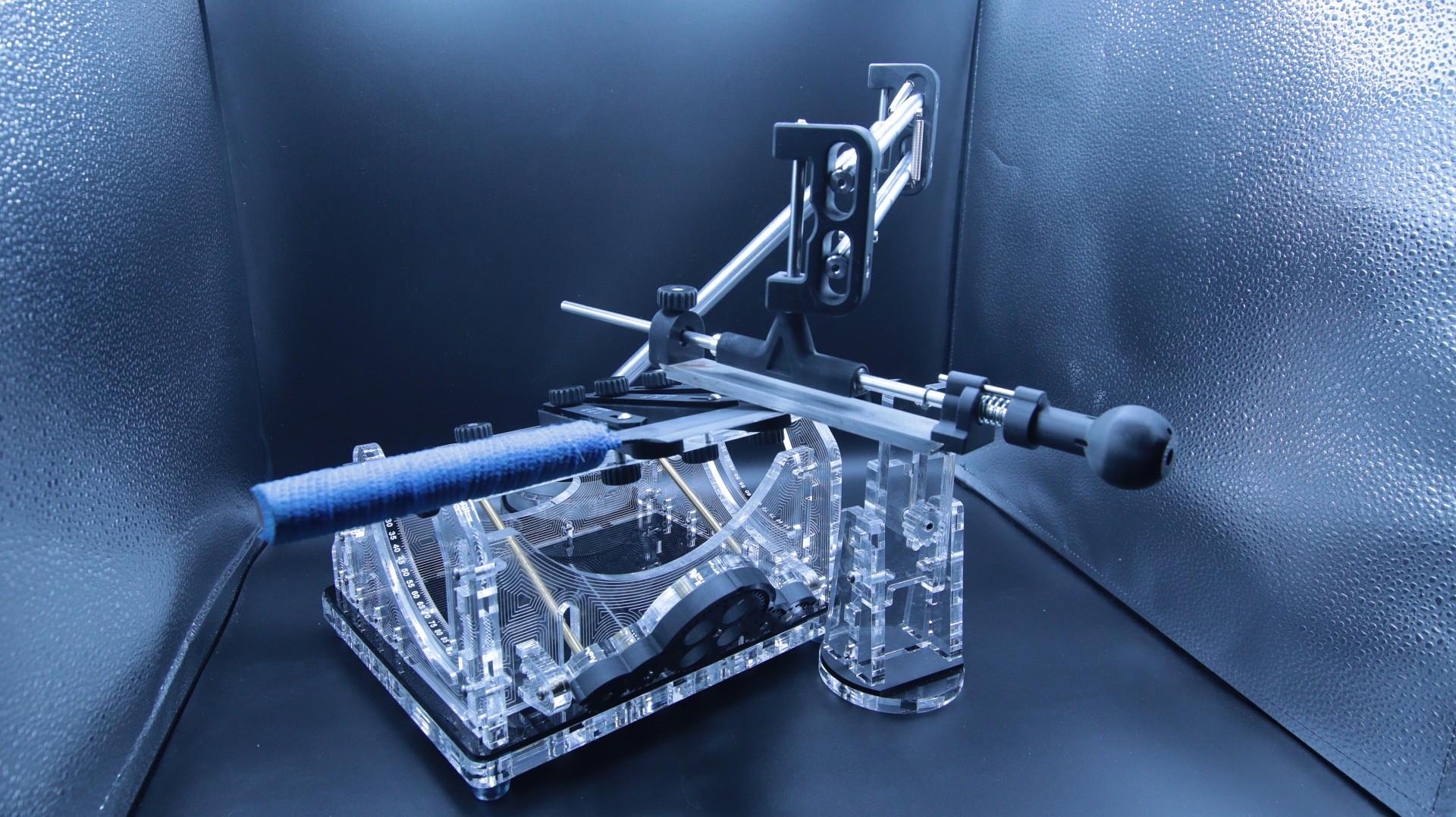

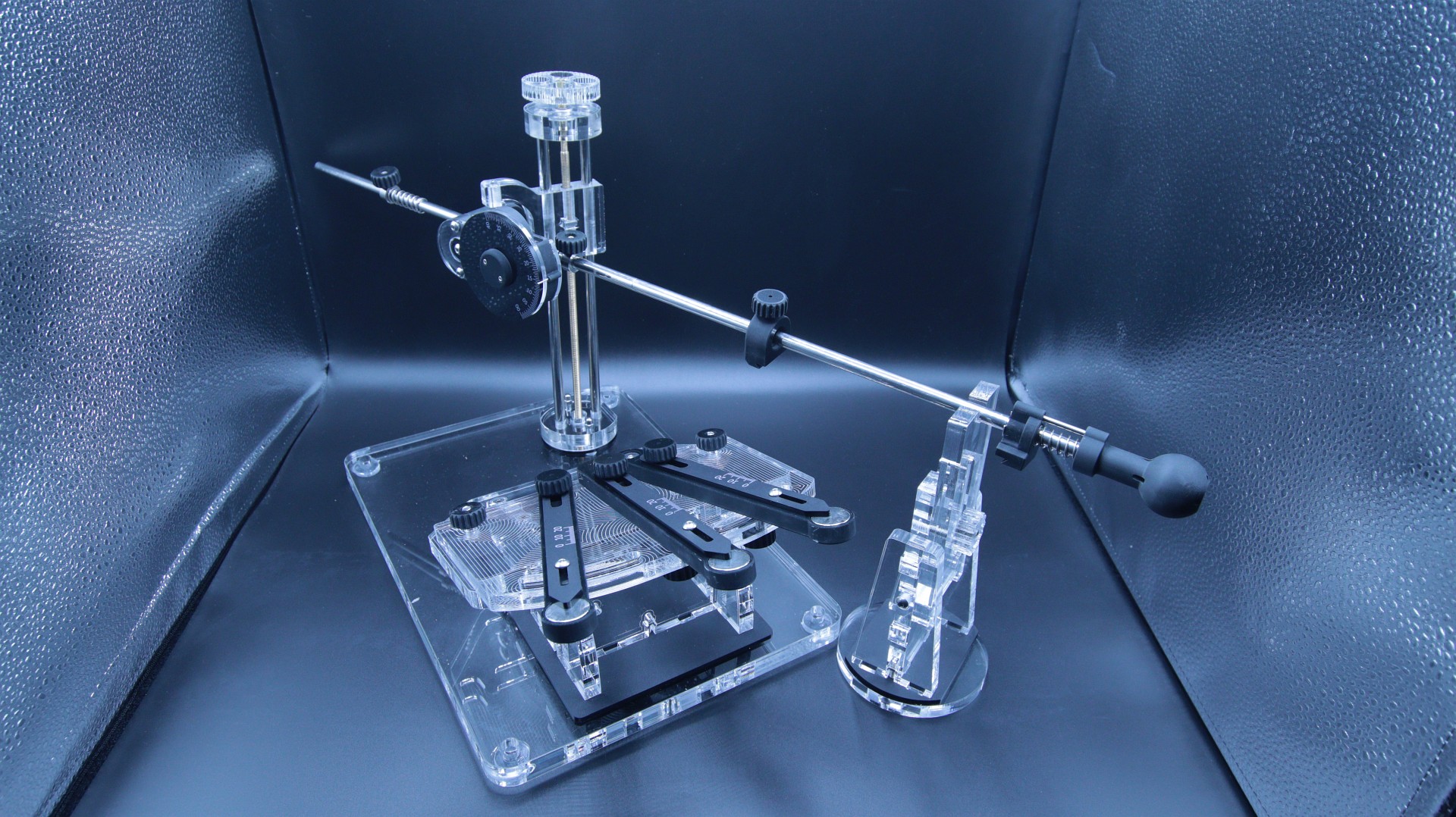

Auch habe ich eine eigene Front Wheel Base aus einem Block entworfen. Hierbei wird der xb-100 von Tormek nicht mehr benötigt. Die dazugehörige Software findet ihr im Shop oder für Android im Playstore

Ermak 10

Die Ermak 10 nutze ich für Messer bei denen der Schleifwinkel perfekt eingehalten werden muss

über die gesamte Schneidenlänge. Hier werden nach und nach noch einige Tests folgen. Ich habe eine

spezielle Maschine für Linkshänder.

Natürlich findet ihr die Ermak 10 auch bei mir im Shop.

Ermak 5

Die Ermak 5 (hab ich ganz neu) wenn ich konvex schleifen möchte oder aber auch ganz konventionell.

Immer mehr Leute erkennen, dass eine konvex geschliffene Schneide deutlich längerer schnitthaltig

bleibt.

Natürlich findet ihr die Ermak 5 auch bei mir im Shop.

Die beiden Ermak-Maschinen könnt ihr euch auf sharpeningtools.eu/de genauer anschauen.

Der Produzent dieser Maschinen ist auch ein „Verrückter“ natürlich im positiven Sinn. Für ihn wie für

mich sind seine Maschinen kleine Kunstwerke die bemerkenswert aussehen und was noch viel

wichtiger ist, exzellente Schärfergebnisse liefern.

Ihr könnt entweder per Überweisung oder per PayPal bezahlen.

Sollte es irgendwelche Probleme geben kontaktiert mich bitte per Mail.

Bleibt gesund

Hanns

tilgert90 –

Die ersten beiden Ergebnisse überzeugen 🤭,das Gerät ist sehr gut verarbeitet und alles ist selbsterklärend.Bei der Messerspitze bedarf es sicher etwas Übung aber das Endergebnis für out of the Box ist erstaunlich 😁.

Verifizierter Kauf. Mehr Informationen

kkh-service.com –

Habe außer der Toolbar noch mehrere Teile bestellt. War alles in einem Packet sehr sorgfältig verpackt. Super !!! Übrigens alle Teile von exzellenter Qualität.

Verifizierter Kauf. Mehr Informationen

Harald Engel –

Schnelle Lieferung, top Ware und sehr gut verpackt.

Verifizierter Kauf. Mehr Informationen